Laboteck Sand Equivalent Shakers: The Superior Choice for Your Laboratory

What is a Sand Equivalent Shaker?

A sand equivalent shaker is a kind of specialized apparatus primarily used in laboratories with an objective to perform the sand equivalent test, an essential test for determining the cleanliness and composition of sand and fine aggregates in construction materials. This test measures the proportion of clay and silt compared to sand in a sample, providing vital information for quality control in concrete and asphalt production.

The sand equivalent shaker facilitates the mixing and agitation of the sand and solution, ensuring accurate and efficient testing results. It's an indispensable tool for construction companies, civil engineers, and material testing laboratories that want to ensure the highest quality and safety standards in their projects.

Technical Parameters:

Speed: Consistent and adjustable speed to ensure proper mixing and agitation.

Capacity: Adequate room to accommodate standard sand equivalent testing cylinders.

Timer: Built-in timer for precise control over shaking time.

Functions and Applications:

Mixing: Efficiently mixes sand, silt, and clay for the sand equivalent test.

Agitation: Ensures uniform and thorough agitation of test materials.

Applications: Commonly used in construction, road building, and aggregate testing laboratories.

Product Features:

Precision Performance: Provides consistent and reliable results with precise control over shaking speed and time.

Durability: Built with high-quality materials for long-lasting performance in demanding lab environments.

Easy to Use: Intuitive controls and straightforward setup for efficient testing.

Safety: Designed with safety features to prevent accidents during operation.

Compact Design: Fits easily in laboratory settings without taking up too much space.

Low Noise: Operates quietly to maintain a calm and productive work environment.

Low Maintenance: Requires minimal upkeep, saving time and resources for lab technicians.

Compliance: Meets industry standards for sand equivalent testing apparatus.

Proper Sand Equivalent Shaker Installation:

Location: Place the shaker on a stable, level surface away from vibration sources.

Power Supply: Ensure the correct voltage and plug type for a reliable power source.

Safety Checks: Verify all parts and accessories are securely fastened and functioning.

Calibration: Calibrate the shaker according to the manufacturer's instructions for optimal accuracy.

Testing: Run a test cycle to confirm proper operation and adjust settings as needed.

Why Choose Laboteck for Your Sand Equivalent Shaker?

Laboteck, a renowned sand equivalent test apparatus manufacturer in Delhi, India, prides itself on delivering high-quality, innovative equipment to laboratories and construction companies across the country. What sets us apart is our unwavering dedication to quality, customer satisfaction, and industry excellence.

Our team of experienced engineers crafts sand equivalent shakers with precision and cutting-edge features to ensure reliable performance. We offer competitive pricing without sacrificing quality, providing exceptional value for your investment. Our knowledgeable support team is always available to offer installation and maintenance advice, ensuring your equipment runs smoothly.

In addition, we offer custom solutions tailored to your specific needs and industry requirements. With efficient manufacturing processes, we guarantee fast delivery of your sand equivalent shaker. Our commitment to quality assurance means every product undergoes rigorous testing for performance and reliability. Trust in Laboteck, the preferred choice for top-notch equipment across India.

Explore our range of sand equivalent shakers and discover why Laboteck is the preferred choice for laboratories across India. Visit our website at laboteck.com to learn more about our products and services.

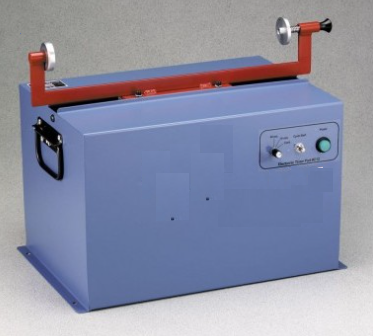

SAND EQUIVALENT MECHANICAL SHAKER – MOTORIZED ASTM 2400

| Overall Dimensions in Inches (L x W x H) | 25 X 19 X 20 |

| Weight (Approx.) | 40 kg |