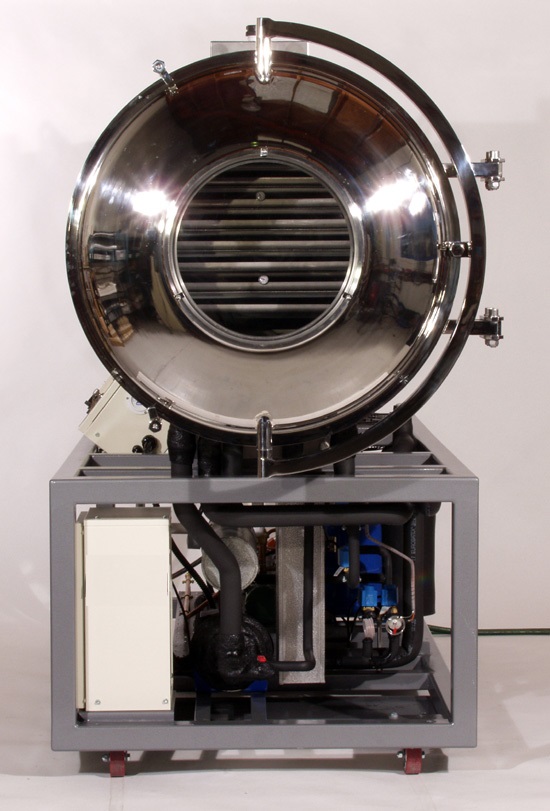

LABORATORY, FOOD & PHARMACEUTICAL FREEZE DRYER (LYOPHILIZER)

The Freeze Dryer (Lyophilizer) is very useful equipment, as in addition to better preserving food, it allows them to be stored more easily, dispensing with the use of very low temperatures and also making them lighter. See a little more about some concepts of freeze-drying, how it works, and other pertinent information. The freeze dryer is equipment capable of promoting lyophilization, making the water from a product be removed, without losing its properties. It has a component that makes it possible to allocate the materials that will be submitted to the procedure, in addition to a tool that reduces the pressure around the product to be dried.

The freeze dryer is essential equipment to efficiently dehydrate a sample or product without losing its properties and nutrients. It is widely used in different areas and can have different types that are specific for some purposes. Products that are not properly dried are also not properly rehydrated, making their quality questionable. With lyophilization, the drying process is efficient and rehydration can be done effectively, making the product of better quality, especially in the food field. The combination of low temperatures and reduced deterioration of the products make the characteristics of these materials easily maintained through lyophilization. Thus, nutrients, color, texture, and flavor are preserved through this process.

FREEZE DRYER FEATURES:

- User-friendly and environmentally friendly

- Easy To Operate

- Water cooling and pressure control system

- Automatic PID control

- Total temperature, vacuum and time control

- CFC/HCFC free refrigerant system

- Reliable refrigerant compressor with low noise

- Meets International Standards

- Low Maintenance

MODELS SPECIFICATIONS: FREEZE DRYER

| Temperature Range | <-50℃ to <-80℃ |

| Pressure | <10Pa |

| Water-Capture Capability Range | 3Kg/24Hr to 6Kg/24Hr |

| Control | Microprocessor |

| Dimensions (LxWxH, mm) | From 380×650×360+30(caster) to 1200×550×880 +70(caster) |

| Lyophilizing Acreage | 0.07 ㎡ to 0.27 ㎡ |

| Power Range | 1100W to 1800W |

| Power Supply | 110-220V/50-60Hz |

WHERE ARE FREEZE DRYERS USED?

The Freeze Dryer is the equipment used in many areas, from research laboratories to the food, pharmaceutical, and technological industries. This equipment uses the freeze-drying process to perform its main function and may have some distinct and suitable types according to the purpose for which they are designed. Lyophilizer is suitable for laboratories, the pharmaceutical industry, and the food industry and is widely used for sample preservation. It can also be applied in food research, making these products more easily packaged, and extending their shelf life.

In The Food Industry:

In the food field, the freeze dryer (lyophilizer) is widely used to dehydrate foods that are intended for instant consumption and also in the preparation of fruits that will be used in certain products. It can be used in milk, so that they are dehydrated without losing its nutrients, preserving their enzymes and proteins.

In The Laboratory & Pharmaceutical Industry:

The pharmaceutical industry and laboratory handle many samples and simple degradation products. To prevent the loss of the characteristics of these products, lyophilization can be a strong ally. It is very important for stabilizing microorganisms in culture and preserving biological specimens, and drugs.

In The Preservation of Objects:

Books and other objects damaged by water can be preserved using freeze-drying techniques. In addition, the preservation of petals and flowers for decorative purposes is also one of the ways to use freeze-drying to maintain the characteristics of objects.

WHAT IS FREEZE-DRYING?

Freeze drying is a separation technique that uses sublimation to dehydrate a product. It consists of three steps that include freezing, de-icing, and separating the water contained in the sample. In the first phase, all the water in the material is turned into ice. After that, the sublimation process takes place, where all the ice previously produced is transformed into steam.

The third step allows the removal of all the water that is still adsorbed to the product, which is transformed into steam. It is a very important process for product maintenance since after this procedure the material does not need to be kept in a refrigerated environment, making storage easier.

HOW DOES THE FREEZE DRYER WORK?

The sample freezing process can be done directly in the lyophilizer or in other equipment that allows this step. In the lyophilizer, the sample is subjected to a pressure drop that occurs with the aid of the device’s vacuum pump.

For the ice contained in the material to change state, going from solid directly to vapor, it is necessary that the temperature be high, preventing the solid sample from being transferred to the liquid state.

WHY BUY YOUR FREEZE DRYER (LYOPHILIZER) WITH LABOTECK?

Laboteck is a trusted distributor & supplier of equipment and accessories for various laboratories, medical, education, and industries. Laboteck offers a high-quality Freeze Dryer (Lyophilizer) for the laboratory, pharmaceutical, and food industry at a fair price, it is interesting to research which one is the most suitable for your needs. Thus, before purchasing this equipment, contact us for the one that best meets your demand. Request a quote now!