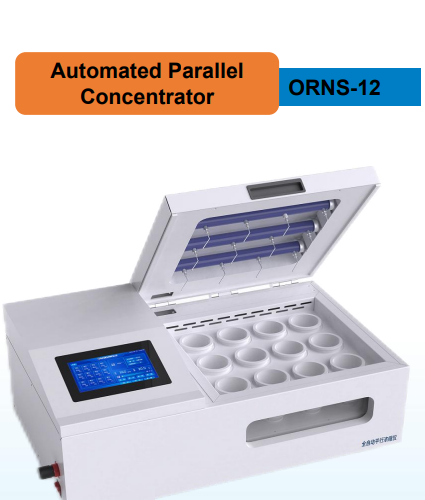

An Automated Parallel Concentrator represents an advanced innovation in sample concentration technology. This sophisticated system is engineered to automate and expedite the concentration process for multiple samples concurrently, marking a significant leap in efficiency for industries such as pharmaceuticals, environmental analysis, and biochemical research.

This cutting-edge technology streamlines concentration procedures by automating the process for multiple samples simultaneously. Through precise control of parameters like temperature, time, and airflow, these concentrators ensure uniform concentration levels across all samples.

This automation significantly reduces processing times, optimizes workflows, and enhances overall efficiency in laboratories and research facilities, making it a pivotal asset in modern sample concentration techniques.

Features of Automated Parallel Concentrator:

- Adjustable blowing needle: The blowing needle can be adjusted in terms of the forward and back ward tilting angle, left-right position, rotation, and replacement.

- Single-channel single-control: Each channel can be individually configured, and all twelve channels can be set to different modes. They can be opened or closed independently without interference.

- Automatic volumetric control: Utilizing high-precision imported optical sensors, it achieves precise volumetric control of 0.5mL/1mL.

- Built-in methods: It has six built-in methods, allowing you to set the method name, operating mode (volumetric, timed, volumetric + timed), and operating time.

- Constant temperature water bath: Equipped with an intelligent AI-PIDd algorithm for precise temperature control, the constant temperature water bath features a water level sensor and automatic low water level alarm.

- Automatic water filling: When the water filling button is pressed, the instrument automatically adds water and stops when reaching the desired water level.

- Lid opening pause: The instrument is equipped with lid opening detection function. When the lid is detected as being opened during normal operation, it automatically stops the nitrogen gas supply and enters a pause mode.

- Lid suspension: It features a lid suspension design, allowing the lid to hover at any position. During the concentration process, when the lid is opened, the nitrogen blowing automatically stops, and when the lid is closed, the nitrogen blowing resumes automatically.

- Control system Vortex blow-off method: Each air passage can be independently controlled, allowing for adjustable airflow during the concentration process.

- Operating system: The instrument comes with a built-in LCD touchscreen that allows direct

parameter settings and real-time display of temperature, pressure, time, and other parameters. The instrument features a visual window design with illumination functionality, facilitating easy

observation. - Heating system: The instrument features a fully enclosed water bath chamber. The inner wall and cover plate in contact with the concentration cup are treated to prevent corrosion and rust. Steam will not rise above the mouth of the concentration cup, preventing steam from entering the concentration cup.

- Parallel Processing: Simultaneously concentrates multiple samples, optimizing throughput and productivity.

- Automation: Offers automated concentration processes, reducing manual intervention and enhancing workflow efficiency.

- Uniform Concentration: Ensures consistent and uniform concentration levels across all samples.

- Precise Control: Allows customization of critical parameters such as temperature, time, and airflow for accurate concentration.

- Sample Versatility: Accommodates various sample types and sizes, catering to diverse experimental needs.

- User-Friendly Interface: Intuitive interface and programmable settings simplify operation and setup.

- High Throughput: Enhances laboratory efficiency by processing multiple samples simultaneously.

- Reduced Processing Time: Drastically reduces the time required for concentration compared to traditional methods.

- Safety Features: Incorporates safety mechanisms to prevent sample degradation or overheating during concentration.

- Compatibility: Compatible with various solvents and sample vessels, ensuring versatility in usage.

- Dimensions and Build: Compact design, occupying minimal space in laboratory setups, and constructed using durable materials for longevity.

An Automated Parallel Concentrator combines automation with precise control, allowing for efficient, simultaneous concentration of multiple samples while offering customizable settings and ensuring consistent results across diverse sample types.

Where Are Automated Parallel Concentrators Used For?

The Automated Parallel Concentrator finds extensive application across various industries and research fields due to its efficiency in sample concentration processes:

- Pharmaceuticals: Used for concentrating active pharmaceutical ingredients (APIs) and formulations, expediting drug development and production processes.

- Environmental Analysis: Vital for concentrating pollutants or contaminants from environmental samples for precise analysis and remediation efforts.

- Biotechnology and Biochemistry: Applied in concentrating biomolecules, proteins, and nucleic acids for research and experimentation.

- Food and Beverage Industry: Utilized to concentrate flavors, aromas, and essential components from natural sources for product development.

- Forensic Sciences: Aids in concentrating compounds critical for forensic investigations, expediting evidence analysis processes.

- Chemical Research: Employed for concentrating various chemicals, aiding in research and development endeavors.

- Academic and Scientific Research: Integral in laboratory settings for concentrating diverse samples across multiple research disciplines.

How Does Automated Parallel Concentrator Works?

The Automated Parallel Concentrator operates by utilizing advanced automation and controlled parameters to streamline sample concentration processes. This innovative system accommodates multiple samples simultaneously, employing precise control over crucial factors like temperature, time, and airflow. Samples undergo concentration through evaporation, facilitated by the application of controlled heat and airflow.

By automating these processes, it expedites concentration without compromising on uniformity or quality. The parallel processing capability optimizes workflow efficiency, reducing processing times significantly compared to conventional concentration methods, thereby enhancing overall productivity in laboratory settings.

Why Buy Your Automated Parallel Concentrator With Laboteck?

Laboteck stands out as an optimal choice for purchasing an Automated Parallel Concentrator due to its commitment to quality, expertise, and customer-centric approach. With Laboteck, you gain access to top-tier equipment known for its reliability and efficiency. They offer unparalleled customer support, ensuring expert guidance during selection, installation, and ongoing maintenance.

Additionally, Laboteck provides competitive pricing without compromising on quality, making them a preferred supplier for laboratories and research facilities seeking cutting-edge technology. Choosing Laboteck ensures access to high-quality Automated Parallel Concentrators backed by a reputable brand known for its commitment to excellence and customer satisfaction.