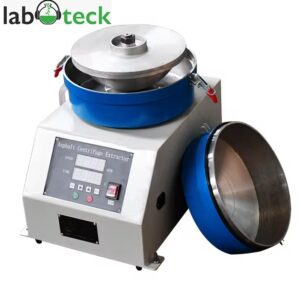

Bitumen Asphalt Extractor / Asphaltic Bitumen Testing Centrifugal Extractor Machine/ Asphalt Centrifuge Extractor Bitumen Separator Analysis/ Asphalt Centrifuge Extractor Binder/ Asphalt Extraction Equipment capacity 1500g or 3000g / AASHTO T164-A ASTM D2172 Centrifugal Asphalt Extractor for determine asphalt content in bituminous mixture

International Standards for Asphalt Extractor : It is designed according to the international standards with relative requirements of ISO, ASTM, JIN, GB and many other testing methods. EN10002-1, ISO 6892, ASTM E8, ASTM C39, ASTM F606, SAE J429, CE Compliant. Below are some standards that must be accord to the machine.

- EN 12697-1

- DIN 1996

- ASTM D2172

- CNR A. VII NO. 38

What is Centrifugal Extractor?

Asphalt Centrifugal Extractor & Flat plate immersions are designed for low temperature working range immersion, drying and extraction. Bitumen Centrifugal extractor has wide application range , where it is used for Bitumen Separator Analysis (determine asphalt content in bituminous mixture). Laboteck is the leading manufacturer of Asphalt centrifugal extractors in India and our machine equipped with explosion proof motor. The Motor must be grounded and place the machine in a ventilated room only.

Asphalt extractor has high speed of 3000 RPM with low noise operation and fast separation speed. The top container of the machine is made of polished steel where sample containers and centrifugal separators are made up of SS 304. The testing process is highly accurate, precise and fast after static and dynamic balance corrections.

Working Principle

Centrifuges extracts the substances from liquid-liquid mixing where heavier particles settles down in bottom and lighter material on top. The centrifugal extractor is very advance, fast and efficient separation equipment that extracts asphalt content from asphalt mixtures. In the bitumen extractor binder machine a high speed motor is used to rotate the drum. When two non mixed liquid samples with different densities completes the mixing and centrifugal force generated during the rotation of drum. At the same time liquid samples quickly separated to two separate outlet points because of high speed rotation of drum. This is the standard procedure of working in the chemical and pharmaceutical industries for plant extraction.

Technical Features:

- Asphalt extraction vessel is made up of high quality Thick Aluminum Alloy

- Instrument shell and centrifugal shaft made up of rust proof stainless steel 304 grade

- Intuitive digital display ensures the smooth working

- According to the precision machine technology

- Centrifugal separator and containers are precisely processed

- Fast separation makes this instrument more convenient and stable

- Light weight machine has compact structure

- High Quality & better Efficiency

- High Quality control system

- Many Models with Novel Design

- Simple Detection Process & Convenient operation

- Low noise and easy maintenance

Application

This Instrument is used for Determination of ductility and the elastic reset of bitumen. Basic application of the instrument is to test the asphalt content in the mixture of asphalt (centrifugal separation method). It may be used at the time of construction of hot-mix hot-paved asphalt mixture pavement to calculate the quality of the mixing plant with asphalt detection.

PRODUCT SPECIFICATIONS

| Product Name | High-Speed Bitumen Asphalt Centrifuge Extractor | |

| Standard | EN 12697-1, ASTM D2172, AASHTO T164A | |

| Model | CT-1500 | CT-3000 |

| Capacity | 1500 gram | 3000 gram |

| Speed | 0 – 3000 R.p.m. (Adjustable) | |

| Pot diameter | 280mm | |

| Power & Load | 220V & 750W | |

| Packing size | 470 x 310 x 540 mm | |

| Weight | 65 KG | 88 KG |